TIredoldparts

Well-Known Member

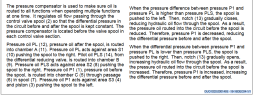

so my 50d is slower on the right side when tracking, doesn't matter when in hi low speed. how do I check pressures on this? I have the manual, but all it shows is how to take apart and put together stuff. I don't see any pressure valves anywhere that pertains to them.

looks like it has both original track motors. around 7500 hrs on it. thanks.

looks like it has both original track motors. around 7500 hrs on it. thanks.