Brianr3989

Member

I can't get this machine to build air past 60 PSI. i have a new compressor and governor. Replace a valve that was leakingbut i can't find anything else that's leaking. Any help would be great at this point.

Good point. I suppose it might be worthwhile to check the pressure at the brake chamber at the same time as you're checking at the compressor exit, but TBH I'd suggest looking at the compressor end first.The brakes won't release at all

heck the main pressure line from the compressor to the wet tank. I

That is one of the ideas I was thinking about in my replies when I suggested hooking an independent source of air to confirm the problem is in the machines compressor or someplace else. Just might not have made it clear what my reasoning was.Check the main pressure line from the compressor to the wet tank. I have had holes or ruptures in those that you can't hear when the machine is running, they don't leak air because of the check valve at the wet tank when you turn the machine off because there is no air in the line to leak, and it will build air to the point that the pressure will overcome what the leak is capable of holding in that line.

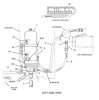

That #2 line in the drawing is the inlet from the cylinder head right?#2 might look like a tube on this illustration but in actual fact it's a Hose As, and as TS mentioned earlier it's of the high-temperature braided stainless steel variety.

View attachment 275790

if this drawing is right