Be4hopper

Active Member

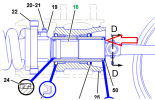

New to HEF but just purchased a 963B and tracks seem a little loose. When backing up And turning it seems to be jumping/ popping on sprockets. Under carriage is CAT and it hasn’t been adjusted since installing I believe.

Any suggestions or instructions will be greatly appreciated!

Any suggestions or instructions will be greatly appreciated!