CotterFCattle

Member

Hello all,

I have a cat 257b serial # SLK05001 I purchased a while back. I am having trouble with the aux hydraulics for a grapple, etc. This is a high flow machine so it has a thumb wheel. Here is what it is doing:

- Pull the thumb wheel down and hydraulics function correctly. With no tool on it labors trying to push oil.

- Release thumb wheel and machine keeps laboring.

- Push thumb wheel up and it quits.

-Pushing up does not make it push oil in other direction.

Please note that I DID try replacing the thumb wheel. I was positive that was the problem, and it was not. Luckily CAT let me return an $1150 handle....

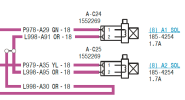

I have tested the solenoids on the valve and they both show the same amount of resistance with a multimeter.

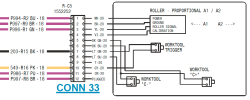

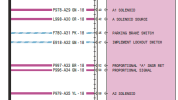

I have used a test light to verify that the connector to one solenoid is receiving power, but the other is not.

Therefore, I have an issue somewhere between the switch harness and the wire that connects to the solenoid. Where should I go next?

I saw that there is something in troubleshooting info from cat about what to do if the switch only works in one direction, but I have not been able to find it.

Thanks!

I have a cat 257b serial # SLK05001 I purchased a while back. I am having trouble with the aux hydraulics for a grapple, etc. This is a high flow machine so it has a thumb wheel. Here is what it is doing:

- Pull the thumb wheel down and hydraulics function correctly. With no tool on it labors trying to push oil.

- Release thumb wheel and machine keeps laboring.

- Push thumb wheel up and it quits.

-Pushing up does not make it push oil in other direction.

Please note that I DID try replacing the thumb wheel. I was positive that was the problem, and it was not. Luckily CAT let me return an $1150 handle....

I have tested the solenoids on the valve and they both show the same amount of resistance with a multimeter.

I have used a test light to verify that the connector to one solenoid is receiving power, but the other is not.

Therefore, I have an issue somewhere between the switch harness and the wire that connects to the solenoid. Where should I go next?

I saw that there is something in troubleshooting info from cat about what to do if the switch only works in one direction, but I have not been able to find it.

Thanks!