Cat 908H 13,600 hours LMD01710

Unit came in with hydraulic leaks and a complaint that the alarm buzzer does not shut off. Other than that seems to be operating fine. Fixed the leaks and pulled it from the shop and it would only crawl. Does NOT have the creep control. full throttle speed does not change, forward or reverse, high or low gear.

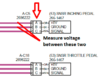

checked the codes. had a few counts for ECM 8V power supply, parking brake sensor, hydro pressure sensor, and unexpected motor speed detection disabled. Replaced all three sensors and codes cleared except for power supply and occasionally the motor speed. checked all fuses, couple questionable ones and incorrect amperage ones. checked all power connections and relays. pulled both ecm connectors in case of corrosion. Everything looks fine, no broke, rubbed or questionable wires. Service manual says to check voltage at connector J1 at pin #44 and 45. Only getting about .7 volts. the next step is to re-flash the ECM. I dont have that flash file so that means a trip to Cat.

My question is what could of happened? Ive not heard of ECMS just taking a crap like that, But even then why is everything else operating normally? Called the tech line and you know how helpful they can be...Anyone else experience this issue? something else to try?

Unit came in with hydraulic leaks and a complaint that the alarm buzzer does not shut off. Other than that seems to be operating fine. Fixed the leaks and pulled it from the shop and it would only crawl. Does NOT have the creep control. full throttle speed does not change, forward or reverse, high or low gear.

checked the codes. had a few counts for ECM 8V power supply, parking brake sensor, hydro pressure sensor, and unexpected motor speed detection disabled. Replaced all three sensors and codes cleared except for power supply and occasionally the motor speed. checked all fuses, couple questionable ones and incorrect amperage ones. checked all power connections and relays. pulled both ecm connectors in case of corrosion. Everything looks fine, no broke, rubbed or questionable wires. Service manual says to check voltage at connector J1 at pin #44 and 45. Only getting about .7 volts. the next step is to re-flash the ECM. I dont have that flash file so that means a trip to Cat.

My question is what could of happened? Ive not heard of ECMS just taking a crap like that, But even then why is everything else operating normally? Called the tech line and you know how helpful they can be...Anyone else experience this issue? something else to try?