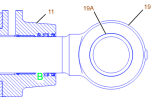

Had a boom cylinder head seal leaking for some time on the 322. Everyone has seen it. I really am not set up at the moment to deal with the extreme torque of the rod nut so I worked with my local hydro shop where I pulled the guts, took them the rod/head assy, they slammed my new seals in, and I thought we were winning. After about 10hrs use, the head was just seeping a touch. I was annoyed but I got stuff to do. Now I am seeing that I am actually back to losing some real oil. Like maybe an ounce a day not even running right now.

Further, I notice the wiper seal is actually driving up! In my mind, I am thinking the main seal is extruding and trying to make an exit. The hydro shop is being insane great and offered to take the whole cylinder and find out what's up but I am nervous they did something damaging in there! Now I guess it could be that oil has been trapped behind the wiper and movement is causing this? IDK! All I know is I have never rebuilt one myself and had these issues. But I do know those CAT seals are insane tight! Way more of a PITA than anything else I have touched.

Further, I notice the wiper seal is actually driving up! In my mind, I am thinking the main seal is extruding and trying to make an exit. The hydro shop is being insane great and offered to take the whole cylinder and find out what's up but I am nervous they did something damaging in there! Now I guess it could be that oil has been trapped behind the wiper and movement is causing this? IDK! All I know is I have never rebuilt one myself and had these issues. But I do know those CAT seals are insane tight! Way more of a PITA than anything else I have touched.