nonprod

Active Member

Hi.

So have another mess to resolve - maybe youse guys can throw me some ideas - forgive me for a lengthy rambling description:

I have a CAT 304 long-stick with the stock thumb cylinder head-end bracketry, fitted with WR buckets, with what I guess is the appropriate bucket adapter. But apparently the original customer requested a thumb, and the dealer had somebody fabricate a rod-end cylinder mount for the CAT 217-2103 thumb assembly - rather than use the normal 14" long pin, thru the end of the stick and bucket adapter, using that pin (208-1498) also for the thumb pivot. (This instead of the normal non-thumb pin, 203-1217). This all (I guess) because of the non-Cat bucket AR)

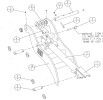

So, they did two rather ugly things (see the pictures): They welded on two 1" thick flanges to the stick with an abomination of a 'tube' (with no zerk) between them, and they lopped off the thumb frame flanges and welded them to the cross bar, about 6" apart. They dropped the bearings (204-4961) used with the 1.57" pins and used some random 2" flag pin. Then they went off to bash it around for some time, such that it is a crazy, wobbly mess.

So long story longer, I have to decide how best to fix it. Maybe there's some reasons to keep the thumb out of the bucket adapter pin design, and some physics I haven't studied as to the thumb pivoting on only a 6" width. But the removal of the bearing design, then having the raw steel bores riding directly on the pin with little or no grease. So with regard to $ and 'doing it correctly,' and as some might say: "It's only a the thumb" etc., what would you guys do - assuming you weren't made of money, like me....?

TIA - gibbs

So have another mess to resolve - maybe youse guys can throw me some ideas - forgive me for a lengthy rambling description:

I have a CAT 304 long-stick with the stock thumb cylinder head-end bracketry, fitted with WR buckets, with what I guess is the appropriate bucket adapter. But apparently the original customer requested a thumb, and the dealer had somebody fabricate a rod-end cylinder mount for the CAT 217-2103 thumb assembly - rather than use the normal 14" long pin, thru the end of the stick and bucket adapter, using that pin (208-1498) also for the thumb pivot. (This instead of the normal non-thumb pin, 203-1217). This all (I guess) because of the non-Cat bucket AR)

So, they did two rather ugly things (see the pictures): They welded on two 1" thick flanges to the stick with an abomination of a 'tube' (with no zerk) between them, and they lopped off the thumb frame flanges and welded them to the cross bar, about 6" apart. They dropped the bearings (204-4961) used with the 1.57" pins and used some random 2" flag pin. Then they went off to bash it around for some time, such that it is a crazy, wobbly mess.

So long story longer, I have to decide how best to fix it. Maybe there's some reasons to keep the thumb out of the bucket adapter pin design, and some physics I haven't studied as to the thumb pivoting on only a 6" width. But the removal of the bearing design, then having the raw steel bores riding directly on the pin with little or no grease. So with regard to $ and 'doing it correctly,' and as some might say: "It's only a the thumb" etc., what would you guys do - assuming you weren't made of money, like me....?

TIA - gibbs