TCat

Well-Known Member

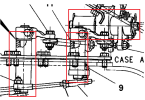

When shifting my dozer into forward, it is very difficult to get it to shift into forward gears. It was this way when I bought it and I'd like to get it working better. It will go in if I play with it and will go into all three gears, but it is very fiddly to get it into the forward three gears. Going into reverse is no problem. I want to adjust the shift linkage and looked up the procedure in the Cat service manual. The problem is I'm not sure where the actual transmission end of the linkage is. I see where the linkage goes into the top of the trans under the floorboard, but I don't see anywhere in the manual where the linkage actually ends. I suspect it's at a valve body on top of the rear of the trans and that I have to take the circled cover off to access it. I just want to make sure before I mess something up not knowing what I'm taking apart. Also If I do need to take that cover off for the adjustment,

if I am correct there are some pressure test ports on that cover. Do those ports just have o-rings that connect them to lines or the valve body directly when you take that cover off?

if I am correct there are some pressure test ports on that cover. Do those ports just have o-rings that connect them to lines or the valve body directly when you take that cover off?

Serial number for the machine is in my signature line.

Thanks in advance everyone.

if I am correct there are some pressure test ports on that cover. Do those ports just have o-rings that connect them to lines or the valve body directly when you take that cover off?

if I am correct there are some pressure test ports on that cover. Do those ports just have o-rings that connect them to lines or the valve body directly when you take that cover off?Serial number for the machine is in my signature line.

Thanks in advance everyone.