Georgia Iron

Senior Member

- Joined

- May 6, 2012

- Messages

- 887

- Location

- USA - Georgia

- Occupation

- Concrete building slab and grading contractor

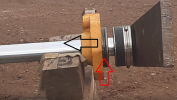

I have a 4 foot long pipe wrench and a nut wrench. I don't believe they are up to the challenge of removing some of the nuts off my used excavator's piston rods.

A local hydraulic shop here uses a floor mount with a forklift pushing on a very big pipe wrench. I was told by a mechanic I know, that they have broken the wrench doing it this way.

Does anyone have any photos / methods of what they use to get the nuts off?

I have been watching several videos on youtube.

Wonder if these hydraulic wrench's will provide enough force.

2 1/2 drive

A local hydraulic shop here uses a floor mount with a forklift pushing on a very big pipe wrench. I was told by a mechanic I know, that they have broken the wrench doing it this way.

Does anyone have any photos / methods of what they use to get the nuts off?

I have been watching several videos on youtube.

Wonder if these hydraulic wrench's will provide enough force.

2 1/2 drive

Hytorc Avanti 20 Hydraulic Angled Torque Wrench 2-1/2" Drive 17,000 Ft Lb USED | eBay

Find many great new & used options and get the best deals for Hytorc Avanti 20 Hydraulic Angled Torque Wrench 2-1/2" Drive 17,000 Ft Lb USED at the best online prices at eBay! Free shipping for many products!

www.ebay.com

Last edited: