-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hydraulic hose clamps

- Thread starter ddk114

- Start date

HarleyHappy

Senior Member

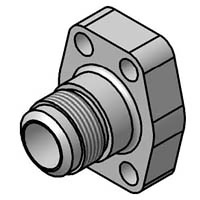

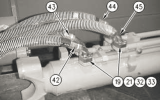

Locks like a code 61 hydraulic fitting and big hydraulic line.

HarleyHappy

Senior Member

Good idea but looks expensive.

Just the 1 1/4” Code 61 90 degree is 91 bucks my cost.

Just the 1 1/4” Code 61 90 degree is 91 bucks my cost.

skyking1

Senior Member

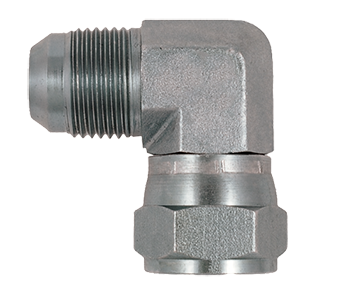

I was thinking have a hose made up with the 90 JIC end . Most hose shops would have that 90.

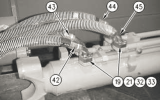

Your going to have to take it apart and bring to hydraulic shop to match to a hose or get id od measurements to see if a hose can be matched up to the fitting Those are old school fittings but the machine hasn't got anymore hyd pressure than it did 50yrs ago if the proper hose can be found the clamp can be reused

Nige

Senior Member

Couple of thoughts.

1. Would a screwed fitting stand the pressure in the system.? It’s obviously pretty substantial if the OEM put a Code 61 flanged fitting there.

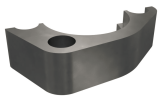

2. It there an option to use the Cat style split clamps on the cylinder then simply have a hose made using a 90-deg Code 61 flange fitting complete with O-ring.? Similar style to the illustration below.

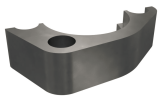

Another possibility is to use clamps similar to those used by Hitachi (and probably others)

www.new-line.com

www.new-line.com

1. Would a screwed fitting stand the pressure in the system.? It’s obviously pretty substantial if the OEM put a Code 61 flanged fitting there.

2. It there an option to use the Cat style split clamps on the cylinder then simply have a hose made using a 90-deg Code 61 flange fitting complete with O-ring.? Similar style to the illustration below.

Another possibility is to use clamps similar to those used by Hitachi (and probably others)

SAE J518 Code 61 and Code 62 4-Bolt Flanges

SAE J518 is commonly used world wide to connect larger sizes of hose and tubing (3/4” to 3”) in fluid power systems. Find Code 61 and Code 62 dimensions.

Last edited:

HarleyHappy

Senior Member

More than likely that will be a 4 wire hose but all you will care about should be system psi.

The Code 61 fittings are used just to mate up with the machined valve blocks, have never seen one on a cylinder before but doesn’t necessarily mean high pressure. It looks like it’s a split adapter for another cylinder.

Any hose shop should be able to get what you need, if they don’t already have it in stock.

I carry Code 61 fittings but only up to 3/4”.

The Code 61 fittings are used just to mate up with the machined valve blocks, have never seen one on a cylinder before but doesn’t necessarily mean high pressure. It looks like it’s a split adapter for another cylinder.

Any hose shop should be able to get what you need, if they don’t already have it in stock.

I carry Code 61 fittings but only up to 3/4”.

OzDozer

Senior Member

The outside diameter of the old hose is not important, the important size is the ID of the hose, and it's cast into the clamp - 1-1/4".

Those old clamp-type bolted up hose couplings are the simplest and best around and you can fix them with minimal tools and at low cost.

No need to go over to crimped hose fittings, just buy a length of Eaton Aeroquip double-braid Hi-impulse hose, unbolt the clamp, cut the old hose off carefully and then pull it off.

Then just skive the outer hose covering off the new Aeroquip hose, slide the new hose on, and bolt up the clamp, and you're right to roll!

These old hydraulic systems only operate at around 2000psi maximum, the Aeroquip hose is rated at 2250psi working pressure in 1-1/4", that's quite adequate for your needs in that application.

hosewarehouse.com

hosewarehouse.com

Those old clamp-type bolted up hose couplings are the simplest and best around and you can fix them with minimal tools and at low cost.

No need to go over to crimped hose fittings, just buy a length of Eaton Aeroquip double-braid Hi-impulse hose, unbolt the clamp, cut the old hose off carefully and then pull it off.

Then just skive the outer hose covering off the new Aeroquip hose, slide the new hose on, and bolt up the clamp, and you're right to roll!

These old hydraulic systems only operate at around 2000psi maximum, the Aeroquip hose is rated at 2250psi working pressure in 1-1/4", that's quite adequate for your needs in that application.

GH195-20 Eaton Aeroquip AQP HI-IMPULSE MATCHMATE BLUE Double Wire Braid Hose

GH195-20 Eaton Aeroquip AQP HI-IMPULSE MATCHMATE BLUE Double Wire Braid Hose meets or exceeds: SAE 100R2AT Type S, EN 853 2SN, ISO 1436-1 Type 2SN. Applications: Petroleum and fire resistant hydraulic fluids, fuel and lubricating systems.