Aussie John

Well-Known Member

- Joined

- Dec 26, 2009

- Messages

- 99

- Location

- Toowoomba, Qld, Australia

- Occupation

- Maintenance Planner, mining equipment

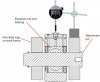

As a part of our maintenance strategy on a fleet of 10 Cat D11 R & T and 3 D10 dozers, the bearing clearances in the equaliser bar need to be checked at regular intervals and recorded. The most accurate method to do this is using a magnetic base dial indicator gauge as shown in the attached illustrations. To do these checks, one has to be close to the gauge to be able to read it and with the engine running to use the blade hydraulics to raise and lower the upper structure, the mechanic is exposed to an unsafe condition. Does anyone know of a remote reading digital dial gauge or precision laser device with a hand-held reader which is suitable for field work. Most digital dial gauges have an RS232 output on them but have not been able to track down the remote reading device. With a cable connected or wireless connection, the mechanic could set up and then sit in the cab to take each reading safely. Another option may be to connect the dial gauge to a notebook computer if there was suitable software available to read the digital dial gauge. Workplace safety rules in the mining industry now prevent anyone being close to or under operating equipment.

John

John