The symptoms I had were once running it was fine. I was getting very small bubbles in the fuel system. Couldn't see them without a flash light behind clear tube. Once it shut off, I guess the air accumulated in the IP. The next start would have enough pressure to run for a few seconds until the air got into the high pressure lines. Then it lost prime. I would have to crank on it for awhile to get prime back and it would run fine again until it shut off. Mine started off intermittent, but got progressively worse.

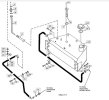

When you installed new rubber hoses, did you happen to remove the union (#2) in Tinkerer's post? The reason I ask is when I removed mine and replaced with new orings (#3 and #4) and the new fuel line, I didn't get the union tight enough and even with the new line on it was still pulling air until I torqued it to what felt like 125 ft-lbs. I couldn't find a torque spec for it.

Mine is all steel lines on the other side of the transfer pump. I suppose you could get air in their, but I would think you'd see fuel since that's a pressure side. The transfer pump is not terribly expensive. That was the first thing I replaced.