Andy1845c

Well-Known Member

Hey all,

I recently purchased a 644B that has been sitting for.... at least 3 years - possibly much longer. I just had the injection pump rebuilt to get it running again and now am working through some other issues and am wondering if anyone has input.

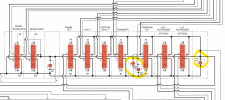

1. When I start it, it takes maybe 30 seconds before the hydraulic functions will actuate. You can hear the engine load a little, like the pump took that long to build pressure. Not sure what to make of this as there are no electronic controls that do anything like this.

2. The steering is "bucky" - seems the worst in crab steer mode. The wheel bounces and fights being turned. Its worse the faster you try and turn it.

3. Fully boomed out at 0 degrees (angle not temp) - I can't raise the boom unless I give it some throttle. Boomed in I can raise it at idle, though slow. Similarly I seem to be fighting the counterbalance valve on the fork curl function - at idle it will move in one direction, but needs some throttle to move the other direction. I did put almost all new hoses on it, and it sat for so long I am sure the system has/had air in it - but I have run it quite a bit now and haven't seen a ton of improvement.

4. I haven't got the transmission to shift. It feels weak. Has trouble getting over minor bumps. I will preface this one by saying I changed the oil and pulled the filter and the filter was awful. The oil was dirty but no water or metal in it. I didn't have a new filter and needed to move it so I cleaned the old one best as I could and put it back in. I have a new one arriving this week. I assume that could cause the issues I am seeing.

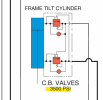

5. I am having a bunch of issues with the frame leveling. someone previously disconnected the front cylinder. Fearing it was full of water or something I took it apart. The inside is fine but one counter balance valve was rusty. I have a new one ordered. Twice now i have suddenly had the frame lean all the way to one side while I was playing with the steering - not even touching the frame control. I don't see how these systems are interconnected.

I have never owned a telehandler before and have limited operator experience so hoping some of you can maybe offer some input.

I recently purchased a 644B that has been sitting for.... at least 3 years - possibly much longer. I just had the injection pump rebuilt to get it running again and now am working through some other issues and am wondering if anyone has input.

1. When I start it, it takes maybe 30 seconds before the hydraulic functions will actuate. You can hear the engine load a little, like the pump took that long to build pressure. Not sure what to make of this as there are no electronic controls that do anything like this.

2. The steering is "bucky" - seems the worst in crab steer mode. The wheel bounces and fights being turned. Its worse the faster you try and turn it.

3. Fully boomed out at 0 degrees (angle not temp) - I can't raise the boom unless I give it some throttle. Boomed in I can raise it at idle, though slow. Similarly I seem to be fighting the counterbalance valve on the fork curl function - at idle it will move in one direction, but needs some throttle to move the other direction. I did put almost all new hoses on it, and it sat for so long I am sure the system has/had air in it - but I have run it quite a bit now and haven't seen a ton of improvement.

4. I haven't got the transmission to shift. It feels weak. Has trouble getting over minor bumps. I will preface this one by saying I changed the oil and pulled the filter and the filter was awful. The oil was dirty but no water or metal in it. I didn't have a new filter and needed to move it so I cleaned the old one best as I could and put it back in. I have a new one arriving this week. I assume that could cause the issues I am seeing.

5. I am having a bunch of issues with the frame leveling. someone previously disconnected the front cylinder. Fearing it was full of water or something I took it apart. The inside is fine but one counter balance valve was rusty. I have a new one ordered. Twice now i have suddenly had the frame lean all the way to one side while I was playing with the steering - not even touching the frame control. I don't see how these systems are interconnected.

I have never owned a telehandler before and have limited operator experience so hoping some of you can maybe offer some input.