RollOver Pete

Senior Member

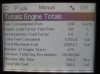

Machine.... Caterpillar D9T.

Total miles (f+r).... around 8111 miles.

Total gallons of fuel consumed... 48,409 gallons.

MPG...... .17 or about 1/8 of a mile per gallon!

Would this qualify me in the fuel guzzler category?

Total miles (f+r).... around 8111 miles.

Total gallons of fuel consumed... 48,409 gallons.

MPG...... .17 or about 1/8 of a mile per gallon!

Would this qualify me in the fuel guzzler category?