-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

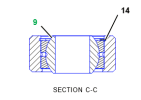

part number for round ring for bearing 197-6439

- Thread starter Ted Allen

- Start date

Nige

Senior Member

Thanks Nige, I have the bearing and I have the retaining rings but the hole that the bearing fits in is a little wallered out. I can have it welded and bored but wanted to see about the cost of the new piece it fits in. Somewhere on here I seen a video of one being cut out and welded back in. None of the schematics I have show that ring!

Nige

Senior Member

yes Nige. that is the one! Thank you for the info!You mean this housing.? See the attachment. If you wanted to go that way I suggest that you check with your dealer that the Part Numbers are current and that they apply to your particular tractor.

View attachment 285011

Last edited:

Nige

Senior Member

Yes, the housing should be oriented with the cap on the bottom. I came across another document stating that even newer blades originally built with the 8-bolt cap should have the housing "flipped" from what is shown in the parts manual if the housing is ever replaced.Does the new housing with the retainer and 8 bolts go on the bottom.

From SEPD0898 - "The blade bearing retainer is now improved on VPAT blades to improve the bearing retention.

The old system with a snap ring can be replaced with a bearing housing using a bolted retainer cap.

Machines already equipped with the bolted retainer cap can also be reworked. The new housing and bolted retainer should be flipped to put the cap underneath.

This is to reduce the axial load in the system during machine application. The changed orientation will prevent bolts from being pulled out."

Nige

Senior Member

Ted, I have thought about this and I'm going to say now that I disagree with the "The new housing and bolted retainer should be flipped to put the cap underneath." Here's why......

The biggest forces on the blade come when the dozer is pushing dirt. Those forces are going to be pushing upwards on the blade as it is pushed downwards into the dirt. So it makes sense to have the "closed" end of the housing at the bottom for when the load comes on it. If the bolted cap was at the bottom then the weight would be directly on the bolts when the blade was pushed down with the hydraulics.

Installing the cap at the top the only time there will be weight on the bolts is when the blade is lifted into the air but in that case the forces involved will only be due to the weight of the blade, and so will be much less than when the blade is in the ground and being pushed downwards.

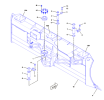

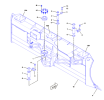

I found this in a Parts Manual for a newer model V-PAT blade that uses the same P/N of bearing and housing clearly showing the cap at the top.

The biggest forces on the blade come when the dozer is pushing dirt. Those forces are going to be pushing upwards on the blade as it is pushed downwards into the dirt. So it makes sense to have the "closed" end of the housing at the bottom for when the load comes on it. If the bolted cap was at the bottom then the weight would be directly on the bolts when the blade was pushed down with the hydraulics.

Installing the cap at the top the only time there will be weight on the bolts is when the blade is lifted into the air but in that case the forces involved will only be due to the weight of the blade, and so will be much less than when the blade is in the ground and being pushed downwards.

I found this in a Parts Manual for a newer model V-PAT blade that uses the same P/N of bearing and housing clearly showing the cap at the top.

Thanks Nige, that clears that up!Yes, the housing should be oriented with the cap on the bottom. I came across another document stating that even newer blades originally built with the 8-bolt cap should have the housing "flipped" from what is shown in the parts manual if the housing is ever replaced.

From SEPD0898 - "The blade bearing retainer is now improved on VPAT blades to improve the bearing retention.

The old system with a snap ring can be replaced with a bearing housing using a bolted retainer cap.

Machines already equipped with the bolted retainer cap can also be reworked. The new housing and bolted retainer should be flipped to put the cap underneath.

This is to reduce the axial load in the system during machine application. The changed orientation will prevent bolts from being pulled out."

Thank you Nige...I can see that!! But don't you think the new bolted on retainer is much more stable and stronger than the snap ring holding the old style in place?Ted, I have thought about this and I'm going to say now that I disagree with the "The new housing and bolted retainer should be flipped to put the cap underneath." Here's why......

The biggest forces on the blade come when the dozer is pushing dirt. Those forces are going to be pushing upwards on the blade as it is pushed downwards into the dirt. So it makes sense to have the "closed" end of the housing at the bottom for when the load comes on it. If the bolted cap was at the bottom then the weight would be directly on the bolts when the blade was pushed down with the hydraulics.

Installing the cap at the top the only time there will be weight on the bolts is when the blade is lifted into the air but in that case the forces involved will only be due to the weight of the blade, and so will be much less than when the blade is in the ground and being pushed downwards.

I found this in a Parts Manual for a newer model V-PAT blade that uses the same P/N of bearing and housing clearly showing the cap at the top.

View attachment 285985

Nige

Senior Member

Absolutely. The new bolted cap would have been a much more robust method than the previous snap ring to secure the spherical bearing into the housing whichever way up it was installed.But don't you think the new bolted on retainer is much more stable and stronger than the snap ring holding the old style in place?

seems to me that the weak point in all these joints is the sleeve that the ball joint is in. Out of the nine spherical bearings i'm replacing, only one of the sleeves survived...all other 8 were broken!!! And my machine only has 6500 hours!