-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Return filter blocked???

- Thread starter Despo1998

- Start date

funwithfuel

Senior Member

You tube, then post a link.

funwithfuel

Senior Member

That looks ugly, but that's a pressure hose, not a suction. If it was leaking, you'd know.

I called a hydraulic mechanic today and got to pick his brain a bit and after going through everything and telling him the filters iv replaced, the screens iv cleaned and how a hydraulic shop had a look at my pump and said it was in perfect condition and after all that he said to change my fluid again. So for the second time iv replaced the fluid and still…nothing

funwithfuel

Senior Member

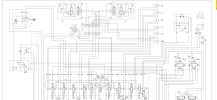

Your service literature, I've been looking at your schematic. You don't seem to have a LS line going back to the pumps. It looks like you have 2 pwm valves controlling pump displacement. If that's the case, your computer must be looking for feedback from a sensor to relay pump demand, then the pwm valves would respond to it by increasing or decreasing control pressure to the swashplate. I don't know if those values are available to you to observe.

The only electronics on the digger is the solenoid block and the 1 and 2 speed solenoids. Iv had a look to see if I missed any other solenoid relays or any as such and nothing, it seems pretty basic I don’t have any sort of ecu or anything

funwithfuel

Senior Member

I'm at a disadvantage here. Can't clearly identify the ports on the RCVs the MCV or the pump. The lines, valves etc are great, it's just when you try to read the ports, things get fuzzy.

funwithfuel

Senior Member

Looking at your pump, P1 & P2 are variable displacement. See that line that goes diagonally across the pumps? That indicates variable. See the dotted line that acts on that lever? That's pump control. It looks like the pump strokes itself as in negative control but the spools shift to block loaf sense, so it seems backwards. The picture is great this time, it just cut off the top.

How many hoses do you have going to your pumps? You should have suction, 2 or 3 discharge, a case drain and control. Can you recall?

How many hoses do you have going to your pumps? You should have suction, 2 or 3 discharge, a case drain and control. Can you recall?

I had another play around tonight on the digger and this is what I found.

this might be a little tricky to understand but I’ll try my best. Okay so I have 3 outlets coming from the pump, P1,P2,P3. We won’t worry about P3 because that goes to the solenoid block. So P1 and P2 both go to the valve block and each side is for left joystick and right joystick, as you know my machine just doesn’t work properly and acts like there is no pressure but at full revs I can get a little bit of control from the left side but nothing from the right side, it won’t even lift the boom. I switched over the hoses tonight and at full revs I can now lift the arm (obviously not quick or how it’s supposed to function) and I haven’t been able to lift it before this. In comparison now the other side controls hardly work. I did notice I have quite a few wear through marks on the (bad) hose/side but no leaking and the horrible vibration/cavitation sound is following the (bad) hose. So I’m not sure if it is the hose or if the pump is just stuffed

this might be a little tricky to understand but I’ll try my best. Okay so I have 3 outlets coming from the pump, P1,P2,P3. We won’t worry about P3 because that goes to the solenoid block. So P1 and P2 both go to the valve block and each side is for left joystick and right joystick, as you know my machine just doesn’t work properly and acts like there is no pressure but at full revs I can get a little bit of control from the left side but nothing from the right side, it won’t even lift the boom. I switched over the hoses tonight and at full revs I can now lift the arm (obviously not quick or how it’s supposed to function) and I haven’t been able to lift it before this. In comparison now the other side controls hardly work. I did notice I have quite a few wear through marks on the (bad) hose/side but no leaking and the horrible vibration/cavitation sound is following the (bad) hose. So I’m not sure if it is the hose or if the pump is just stuffed

funwithfuel

Senior Member

If we were talking about damage to a suction hose, yes, that would be a concern. But on a pressure hose or delivery, any damage not leaking is inconsequential to our troubleshooting. If your pump is in good order, the pump shop said you were good. Their job is to sell you stuff. Why would they fudge when they could make a buck? Let's look at your relief valves. Has anyone, to your knowledge, adjusted them? Are the jam-nuts tight? It's hard to believe that could be the issue, but we can't rule it out.I had another play around tonight on the digger and this is what I found.

this might be a little tricky to understand but I’ll try my best. Okay so I have 3 outlets coming from the pump, P1,P2,P3. We won’t worry about P3 because that goes to the solenoid block. So P1 and P2 both go to the valve block and each side is for left joystick and right joystick, as you know my machine just doesn’t work properly and acts like there is no pressure but at full revs I can get a little bit of control from the left side but nothing from the right side, it won’t even lift the boom. I switched over the hoses tonight and at full revs I can now lift the arm (obviously not quick or how it’s supposed to function) and I haven’t been able to lift it before this. In comparison now the other side controls hardly work. I did notice I have quite a few wear through marks on the (bad) hose/side but no leaking and the horrible vibration/cavitation sound is following the (bad) hose. So I’m not sure if it is the hose or if the pump is just stuffed

Were you able to find a description of your pump as to how it receives its signal to stroke up?

Last edited:

I did have a mechanic come out briefly on his way through to another job and he took the main relief valves out and inspected them, springs and orings and said they looked good and played around with the adjustment but no matter what he did it didn’t change any values or anything performance wise

funwithfuel

Senior Member

I'm gonna keep thinking on this one.