Hello masters!

I have problems on my excavator regarding the slew not stopping. I got myself a manual and some measuring equipment like you already advised me.

So the problem is that sometimes when releasing the joystick command the upper structure doesn’t come to an end. But not always.

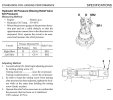

I did a test on the slew motor today according to the manual. I tested on the two ports that I circled on the photo. When using the control they both come up to spec at about 32MPa. When releasing they drop immediately to zero thats on the occasions when the slewing stops. At times when the slewing doesn’t stop the pressure drops from 32MPa to 20MPa, so there is still oil coming to the slew system, but I don’t really know how since I haven’t ever worked on hydraulics and this is my first excavator.

I would like to know what to make of this and what would be the next step to narrow down the problem and come to the cause of it.

And is the pressure dropping immediately to zero after releasing the control normal? Because when the slewing stops it always stops abruptly almost lifting the track on one side and I really fell like it’s abusing the machine…

I have problems on my excavator regarding the slew not stopping. I got myself a manual and some measuring equipment like you already advised me.

So the problem is that sometimes when releasing the joystick command the upper structure doesn’t come to an end. But not always.

I did a test on the slew motor today according to the manual. I tested on the two ports that I circled on the photo. When using the control they both come up to spec at about 32MPa. When releasing they drop immediately to zero thats on the occasions when the slewing stops. At times when the slewing doesn’t stop the pressure drops from 32MPa to 20MPa, so there is still oil coming to the slew system, but I don’t really know how since I haven’t ever worked on hydraulics and this is my first excavator.

I would like to know what to make of this and what would be the next step to narrow down the problem and come to the cause of it.

And is the pressure dropping immediately to zero after releasing the control normal? Because when the slewing stops it always stops abruptly almost lifting the track on one side and I really fell like it’s abusing the machine…