Nige

Senior Member

Is the Serial Number prefix of the one in the photos 43N.? Do you have a full Serial Number perchance.?

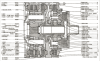

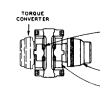

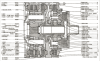

The 825B shares the same 3-speed powershift transmission as the 36H-prefix 824B Wheel Dozer so parts shouldn't be a problem. I'd imagine a lot of internal parts such as clutch discs, plates, seals, bearings, etc, are also common with a wide range of other models apart from the 824B

There are literally thousands of D343 engines still around and I am not aware of any major issues with parts availability, either OEM or aftermarket. Hopefully others can confirm that.

The 825B shares the same 3-speed powershift transmission as the 36H-prefix 824B Wheel Dozer so parts shouldn't be a problem. I'd imagine a lot of internal parts such as clutch discs, plates, seals, bearings, etc, are also common with a wide range of other models apart from the 824B

There are literally thousands of D343 engines still around and I am not aware of any major issues with parts availability, either OEM or aftermarket. Hopefully others can confirm that.