colson04

Senior Member

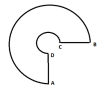

Well, my 10 year old outdoor wood boiler (Ridgewood brand - no longer around) developed a slight water leak. I got the front tore off and found I have cracks in all 4 corners of the door. 2 radiating straight up, 2 going straight down. Cracks propagating like this suggest a design failure (square door opening inside round firebox- different rates of expansion causing fatigue over time).

Either way, one crack made it to the weld between the firebox and water chamber causing a slow leak.

It leaks water into fire box and through the crack to the outside. The other 3 cracks haven't breached the water chamber, but if i dont address them now, they will. The outside of the firebox on the front had fiberglass insulation that was soaked, holding moisture against the steel for awhile causing surface corrosion. I'm presuming it slowly leaked for quite a while before it got bad enough for us to see the water coming out the bottom.

My instinct is to grind out the cracks, and weld them up. I don't have extensive welding repair knowledge to know if that is best option, or if that would fail the first time I light the fire. Is there a procedure that is better for this type of work? Preheat? Welding wire/rod selection? I have a Hobart 190 wire feed, and I also have a Lincoln 225 tombstone as my personal welders. I have a 100amp service in my barn so I don't lack power to run them either. The welding positions will be vertical, and overhead to repair the crack inside the boiler.

Thoughts?

Either way, one crack made it to the weld between the firebox and water chamber causing a slow leak.

It leaks water into fire box and through the crack to the outside. The other 3 cracks haven't breached the water chamber, but if i dont address them now, they will. The outside of the firebox on the front had fiberglass insulation that was soaked, holding moisture against the steel for awhile causing surface corrosion. I'm presuming it slowly leaked for quite a while before it got bad enough for us to see the water coming out the bottom.

My instinct is to grind out the cracks, and weld them up. I don't have extensive welding repair knowledge to know if that is best option, or if that would fail the first time I light the fire. Is there a procedure that is better for this type of work? Preheat? Welding wire/rod selection? I have a Hobart 190 wire feed, and I also have a Lincoln 225 tombstone as my personal welders. I have a 100amp service in my barn so I don't lack power to run them either. The welding positions will be vertical, and overhead to repair the crack inside the boiler.

Thoughts?