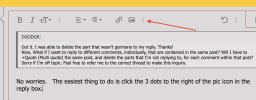

I haven't been on HEF much since it went through it's last remodel. I'd have to say that I don't see how to quote parts of a post separately (i.e. replying to individual paragraphs, sentences, or photos) like we used to be able to. I hope that someone can show me how as I am going to only reply to certain comments within CM's last post, and don't want to re-post the whole thing to do so.

CM1995:

This one is coming with full auto Trimble GPS. Actually waiting on the newest receivers for the machine. Full auto has worked so well on our D3 that it was just a matter of time to get the system on a 325.

Me:

I hope that it works well for you. As I'm sure you know, those systems have been around for dozers for quite some time now, and as far as machine control goes, only have to deal with the up and down of the blade. Furthermore, the excavators have a lot more moving axes, so I would imagine it would be much harder to make the system work well. I may have pulled the trigger but my jobs are in very remote locations (can't relly on cell reception) and there are lots of trees and mountains to interfere with satellite reception too.

CM1995:

Are those Stucchi quick couplers? If so, how have they held up?

Me:

Yes, those are Stucchi couplers. As you may recall from another thread, I have had a lot of issues with them. The ones in the last photo are "-17" size (Stucchi reference for 1"), and I had a lot of them fail. So far, it seems that a lot of my issues might be due to the fact that the machine is equipped with a thumb, and routing the auxiliary hoses, from the end of the hard line, to the attachment is difficult because of how wide the thumb is, and the location of the end of the hard line relevant to the dog bone link. In th epast I have resorted to using 90's between the attachment side of the Stucchi, and the hydraulic hose of the attachment. After several conversations with Stucchi, they felt as though it boiled down to (2) possible issues. First, that the angle fitting was so close to the Stucchi coupler, that the turbulence it caused was cutting the seals in it. Next, they thought it might be because the GPM was above what the -17's were rated for (by only a GPM or two). This was only true for the crusher, not for the hammer, or ho-pac, and I only observed seal failures while using the hammer and ho-pac (Odd!). Ultimately, I removed the dipper hardlines on both the 325 and the 245G. On the 325 we installed shorter hoses, and on the Deere we found shorter Deere hardlines. I had a local hydraulic shop quote me to build new, shorter hard lines for the 325 but they were way to expensive ($2,700 IIRC). My CAT delaer installed the hoses at no charge (and let me keep the original hardlines too!). Thank you Wagner Equipment!!! Now that I have more distance to get around the thumb, we have eliminated the 90's. I also upsized the couplers to "-21" (Stucchi jargine for 1-1/4"). This was a substantial investment. It also required that I re-mount the dipper lines farther away from the dipper to make room for the larger diameter of the coupler. So far, I have not yet had any failures since taking both of those measures. We didn't get this completed until spring so the jury is still out as we haven't even had a full season on them since we made the changes. I will, however, say that we didn't space the lines farther out from the dipper on the Deere yet and, while the -21's do fit, they are a PIA to swap out because my fingers don't fit between the coupler and the dipper. This makes them hard to put on and take off since there is a fair amount of threads to cover.

CM1995:

Machine without GPS was $277K with no QC or bucket however that includes a manual thumb at $7K and the medium pressure line which was a $15K dealer installed option. So the machine with bare stick was around $255K for comparison. In 2018 our 325FL was $212K IIRC.

Me:

As I recall it, my 325 purchase included the 18k# counterweight, hydraulic thumb, hydraulic bucket coupler, 24" and 48" severe duty CAT buckets, the laser catch (machine mounted receiver), auxiliary lines, high ambient cooling package, (3) foot pedals (traditional two, and a single F&R pedal as well). I purchased in December of '21, in S/W CO, for $274K. I bought my Deere 245G (similarly equipped but w/o any of the 2D machine control, e-fence, scales, etc.) for $254k in 2017.

In comparison, the 325 is more comfortable, has MUCH more room in the cab, has A/C that actually will keep the cab cool (which is nice), but also the super structure has more room which makes it easier to service, and also allows one to carry tools, teeth, and even fluids if you want. It also is the machine of choice if the digging gets hard. On the other hand, the 245G is a true "zero tail". Having a zero tail is great! "If the tracks fit, the tail won't hit" (when on flat ground anyway). The Deere is smoother, faster, and is much easier to modulate. I think that Deere/Hitachi really had the hydraulics sorted out well. Of course, the 245 is still hydraulic pilot control. Even still, the Deere is smoother than any CAT pilot controlled I've run as well.

CM1995 (I'm paraphrasing):

I kept the buckets from the F machine because I can get K style teeth in the aftermarket at half the price.

Me:

No sense in buying buckets unless one can realize an expense overiding benefit. I have had good luck with my K style teeth. I have lost many J style but I have never had a K style tooth fall off. When I have mentioned this to others in the past, I have had many complain about loosing K style teeth. I went with the CAT Advansys teeth for my 325. I liked the idea of the quarter turn retention system. I have not yet lost, or broken a tooth. To that end, I have always had CAT teeth perform very well. This only happened to me once, but I did break a CAT tiger tooth. When I went to replace it, CAT gave me a new for free under warranty. It was explained to me that CAT teeth are warranted against breaking. Regardless, I have penetration plus teeth and they are the original teeth that were delivered with the machine. Now, I only have 900 hours on the machine so far, but the teeth have gone that long as well. Mind you, I am working in solid rock, shot rock, crushed rock, with boulders, etc. (only a small amount of dirt), and they have gone 900 hours so far. I did buy a set recently to have on hand when the originals are done. The (6) teeth required for my 48" bucket were expensive. IIRC they were $125 each. Still, at .75 per hour (I assume that they will likely make it to 1,000 hrs), in the worst conditions possible, I think that's a value. I would assume that they may go to 1,300, or 1,400 hours if only going through dirt. I would love to hear about aftermarket success stories. What is your experience with teeth? Do you know how many hours your getting, and/or cost per hour (You seem like the kind of person who would)? From your thread, it seems like you are mostly in dirt with occasional rock. Is that how you would describe it?

SAVMAN:

I wonder how it will do on fuel and power compared to the 325f?

Another thing I have wondered...if you look at the specs of a 323 vs 325; they're listed as having the same hp....but the 323 has a 7.1 vs a 4.4 in the 325.....no way they are burning the same fuel...right?

I'm due for an upgrade myself and I've toyed with the idea of a 323 and I'll still have the 321 for tight spots.....idk

One thing that stood out to me, is you've said the 325f is stronger and burns less fuel than the 321; I wonder if the nextgen will be even more fuel efficient.

Me:

In my experience, 6 cylinders will burn more fuel than 4. I have an '03 CAT 315c with a 6 cylinder Mitsubishi engine. When I bought the machine new, the 6 banger was one of the benefits in my mind (all the other competitors, save for Volvo) had 4 cyl engines). The 315c (tier 2 @ 110 hp) burns about 40 gallons if digging a full day. By comparison, my 2017 Deere 245G has a 4 cylinder Isuzu engine (tier 4 @ 159 hp) burns the same 40 gallons if digging a full day.

I haven't looked that closely at fuel consumption on the CAT 325. I think it would be about the same as the Deere but my impression is that it might consume a bit more. This makes sense if the CAT is rated at 172 hp vs Deere's 159 hp. I thought that I had heard (maybe from my sales rep) that CAT was putting Fiat 4 cylinder engines in the F model 325's. Can anyone verify that? Is that still true with the NG 325's? Please don't report back with "It says CAT right on the motor, so it must be made by CAT"! Cat has been putting their name on Perkins, Mitsubishi, Kubota, etc., etc, for decades. I have heard nothing but good things about the Izusu 4cyl, but nothing about Fiat's. I certainly don't feel warm and fuzzy with the idea of a Fiat engine in my 325. That's probably due to what I saw growing up. Fiat cars were not very reliable, so I have observed that I don't have much faith in the brand.

CM1995:

This one is coming with full auto Trimble GPS. Actually waiting on the newest receivers for the machine. Full auto has worked so well on our D3 that it was just a matter of time to get the system on a 325.

Me:

I hope that it works well for you. As I'm sure you know, those systems have been around for dozers for quite some time now, and as far as machine control goes, only have to deal with the up and down of the blade. Furthermore, the excavators have a lot more moving axes, so I would imagine it would be much harder to make the system work well. I may have pulled the trigger but my jobs are in very remote locations (can't relly on cell reception) and there are lots of trees and mountains to interfere with satellite reception too.

CM1995:

Are those Stucchi quick couplers? If so, how have they held up?

Me:

Yes, those are Stucchi couplers. As you may recall from another thread, I have had a lot of issues with them. The ones in the last photo are "-17" size (Stucchi reference for 1"), and I had a lot of them fail. So far, it seems that a lot of my issues might be due to the fact that the machine is equipped with a thumb, and routing the auxiliary hoses, from the end of the hard line, to the attachment is difficult because of how wide the thumb is, and the location of the end of the hard line relevant to the dog bone link. In th epast I have resorted to using 90's between the attachment side of the Stucchi, and the hydraulic hose of the attachment. After several conversations with Stucchi, they felt as though it boiled down to (2) possible issues. First, that the angle fitting was so close to the Stucchi coupler, that the turbulence it caused was cutting the seals in it. Next, they thought it might be because the GPM was above what the -17's were rated for (by only a GPM or two). This was only true for the crusher, not for the hammer, or ho-pac, and I only observed seal failures while using the hammer and ho-pac (Odd!). Ultimately, I removed the dipper hardlines on both the 325 and the 245G. On the 325 we installed shorter hoses, and on the Deere we found shorter Deere hardlines. I had a local hydraulic shop quote me to build new, shorter hard lines for the 325 but they were way to expensive ($2,700 IIRC). My CAT delaer installed the hoses at no charge (and let me keep the original hardlines too!). Thank you Wagner Equipment!!! Now that I have more distance to get around the thumb, we have eliminated the 90's. I also upsized the couplers to "-21" (Stucchi jargine for 1-1/4"). This was a substantial investment. It also required that I re-mount the dipper lines farther away from the dipper to make room for the larger diameter of the coupler. So far, I have not yet had any failures since taking both of those measures. We didn't get this completed until spring so the jury is still out as we haven't even had a full season on them since we made the changes. I will, however, say that we didn't space the lines farther out from the dipper on the Deere yet and, while the -21's do fit, they are a PIA to swap out because my fingers don't fit between the coupler and the dipper. This makes them hard to put on and take off since there is a fair amount of threads to cover.

CM1995:

Machine without GPS was $277K with no QC or bucket however that includes a manual thumb at $7K and the medium pressure line which was a $15K dealer installed option. So the machine with bare stick was around $255K for comparison. In 2018 our 325FL was $212K IIRC.

Me:

As I recall it, my 325 purchase included the 18k# counterweight, hydraulic thumb, hydraulic bucket coupler, 24" and 48" severe duty CAT buckets, the laser catch (machine mounted receiver), auxiliary lines, high ambient cooling package, (3) foot pedals (traditional two, and a single F&R pedal as well). I purchased in December of '21, in S/W CO, for $274K. I bought my Deere 245G (similarly equipped but w/o any of the 2D machine control, e-fence, scales, etc.) for $254k in 2017.

In comparison, the 325 is more comfortable, has MUCH more room in the cab, has A/C that actually will keep the cab cool (which is nice), but also the super structure has more room which makes it easier to service, and also allows one to carry tools, teeth, and even fluids if you want. It also is the machine of choice if the digging gets hard. On the other hand, the 245G is a true "zero tail". Having a zero tail is great! "If the tracks fit, the tail won't hit" (when on flat ground anyway). The Deere is smoother, faster, and is much easier to modulate. I think that Deere/Hitachi really had the hydraulics sorted out well. Of course, the 245 is still hydraulic pilot control. Even still, the Deere is smoother than any CAT pilot controlled I've run as well.

CM1995 (I'm paraphrasing):

I kept the buckets from the F machine because I can get K style teeth in the aftermarket at half the price.

Me:

No sense in buying buckets unless one can realize an expense overiding benefit. I have had good luck with my K style teeth. I have lost many J style but I have never had a K style tooth fall off. When I have mentioned this to others in the past, I have had many complain about loosing K style teeth. I went with the CAT Advansys teeth for my 325. I liked the idea of the quarter turn retention system. I have not yet lost, or broken a tooth. To that end, I have always had CAT teeth perform very well. This only happened to me once, but I did break a CAT tiger tooth. When I went to replace it, CAT gave me a new for free under warranty. It was explained to me that CAT teeth are warranted against breaking. Regardless, I have penetration plus teeth and they are the original teeth that were delivered with the machine. Now, I only have 900 hours on the machine so far, but the teeth have gone that long as well. Mind you, I am working in solid rock, shot rock, crushed rock, with boulders, etc. (only a small amount of dirt), and they have gone 900 hours so far. I did buy a set recently to have on hand when the originals are done. The (6) teeth required for my 48" bucket were expensive. IIRC they were $125 each. Still, at .75 per hour (I assume that they will likely make it to 1,000 hrs), in the worst conditions possible, I think that's a value. I would assume that they may go to 1,300, or 1,400 hours if only going through dirt. I would love to hear about aftermarket success stories. What is your experience with teeth? Do you know how many hours your getting, and/or cost per hour (You seem like the kind of person who would)? From your thread, it seems like you are mostly in dirt with occasional rock. Is that how you would describe it?

SAVMAN:

I wonder how it will do on fuel and power compared to the 325f?

Another thing I have wondered...if you look at the specs of a 323 vs 325; they're listed as having the same hp....but the 323 has a 7.1 vs a 4.4 in the 325.....no way they are burning the same fuel...right?

I'm due for an upgrade myself and I've toyed with the idea of a 323 and I'll still have the 321 for tight spots.....idk

One thing that stood out to me, is you've said the 325f is stronger and burns less fuel than the 321; I wonder if the nextgen will be even more fuel efficient.

Me:

In my experience, 6 cylinders will burn more fuel than 4. I have an '03 CAT 315c with a 6 cylinder Mitsubishi engine. When I bought the machine new, the 6 banger was one of the benefits in my mind (all the other competitors, save for Volvo) had 4 cyl engines). The 315c (tier 2 @ 110 hp) burns about 40 gallons if digging a full day. By comparison, my 2017 Deere 245G has a 4 cylinder Isuzu engine (tier 4 @ 159 hp) burns the same 40 gallons if digging a full day.

I haven't looked that closely at fuel consumption on the CAT 325. I think it would be about the same as the Deere but my impression is that it might consume a bit more. This makes sense if the CAT is rated at 172 hp vs Deere's 159 hp. I thought that I had heard (maybe from my sales rep) that CAT was putting Fiat 4 cylinder engines in the F model 325's. Can anyone verify that? Is that still true with the NG 325's? Please don't report back with "It says CAT right on the motor, so it must be made by CAT"! Cat has been putting their name on Perkins, Mitsubishi, Kubota, etc., etc, for decades. I have heard nothing but good things about the Izusu 4cyl, but nothing about Fiat's. I certainly don't feel warm and fuzzy with the idea of a Fiat engine in my 325. That's probably due to what I saw growing up. Fiat cars were not very reliable, so I have observed that I don't have much faith in the brand.

Last edited: