joelx777

Well-Known Member

Thank you all for your help!

My John Deere 490e excavator has an issue where pressing down with the boom can randomly become weak after operating it for 20-30 minutes or so. Usually, pressing down with the bucket on the ground will lift the machine off it's tracks, but when this error occurs the machine will no longer lift up or press down to push dirt. I can still lift the boom up with load on it or push down with no load (not pushing the ground). If I shut the machine down and return to it later, everything works fine, at least for awhile. I am guessing it is a valve that is sticking when it gets hot somewhere?

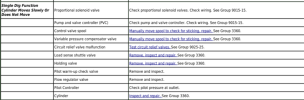

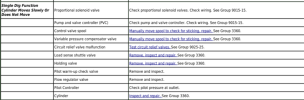

Here is what my manual says to do in this situation:

My problem is that as a newbie, I am unsure how to do these tasks. I completed an online course in diesel mechanics and have spent 40 hours in a hydraulics course so far. I know the principles, but the actual hands on work is not something I have done enough of, but I am trying to get more experience.

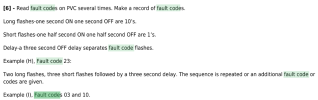

I looked up the proportional solenoid valve referenced (group 9015-15), but all it shows there is how to use a wiring test harness that is no longer made or sold anywhere.

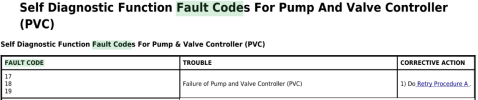

For the pump and valve controller step, I don't have the computer. I saw I can interpret the blinking lights, but haven't had the cover off yet. I asked a gentleman from this forum who posted years ago that he had the software to send it, but have not heard back.

I have no idea how to manually move the control valve spool and variable pressure compensator valves to check for sticking or how to repair these. Group 3360 in the manual is just how to disassemble / reassemble these.

And so on.

I would really appreciate any advice or insight or direction you could provide!

P.S. - I am also considering buying some PSI test gauges, but don't know exactly what to get. My manuals (tm1504 and tm1505) do not specify exactly what I would need as I am guessing that since these manuals were written for JD mechanics, they assume the mechanics have them already.

Also - I ran through the cycle time test in the manual today, the complete results are below... the strange thing is that boom lower operates almost at the new spec whereas most of the other functions operate slower (it's an old machine) near the max spec:

Boom raise spec 3.2 max 4.3 seconds

Actual 4.2

Boom 4 lower spec 2.5 max 3.9 seconds

Actual 2.8

Arm in spec 3.9 max 5.5

Actual 5.2

Arm extend spec 2.6 max 3.6

Actual 3.1

Bucket load spec 2.6 max 3.4

Actual 3.7

Bucket dump spec 1.8 max 2.6

Actual 3?

Swing left or right 3 revolutions from running start 16.4 max 21.7

Actual 11

Propel 20 meters normal speed 21 seconds max speed 13 seconds slow speed 29 seconds

Actual slow 38

Actual normal 20

Actual max 19l

Propel track raised at max speed 3 revolutions from running start spec 14.5 max 19.0

Actual right 21.8

Actual left 20.5 but very shaky and noisy

My John Deere 490e excavator has an issue where pressing down with the boom can randomly become weak after operating it for 20-30 minutes or so. Usually, pressing down with the bucket on the ground will lift the machine off it's tracks, but when this error occurs the machine will no longer lift up or press down to push dirt. I can still lift the boom up with load on it or push down with no load (not pushing the ground). If I shut the machine down and return to it later, everything works fine, at least for awhile. I am guessing it is a valve that is sticking when it gets hot somewhere?

Here is what my manual says to do in this situation:

My problem is that as a newbie, I am unsure how to do these tasks. I completed an online course in diesel mechanics and have spent 40 hours in a hydraulics course so far. I know the principles, but the actual hands on work is not something I have done enough of, but I am trying to get more experience.

I looked up the proportional solenoid valve referenced (group 9015-15), but all it shows there is how to use a wiring test harness that is no longer made or sold anywhere.

For the pump and valve controller step, I don't have the computer. I saw I can interpret the blinking lights, but haven't had the cover off yet. I asked a gentleman from this forum who posted years ago that he had the software to send it, but have not heard back.

I have no idea how to manually move the control valve spool and variable pressure compensator valves to check for sticking or how to repair these. Group 3360 in the manual is just how to disassemble / reassemble these.

And so on.

I would really appreciate any advice or insight or direction you could provide!

P.S. - I am also considering buying some PSI test gauges, but don't know exactly what to get. My manuals (tm1504 and tm1505) do not specify exactly what I would need as I am guessing that since these manuals were written for JD mechanics, they assume the mechanics have them already.

Also - I ran through the cycle time test in the manual today, the complete results are below... the strange thing is that boom lower operates almost at the new spec whereas most of the other functions operate slower (it's an old machine) near the max spec:

Boom raise spec 3.2 max 4.3 seconds

Actual 4.2

Boom 4 lower spec 2.5 max 3.9 seconds

Actual 2.8

Arm in spec 3.9 max 5.5

Actual 5.2

Arm extend spec 2.6 max 3.6

Actual 3.1

Bucket load spec 2.6 max 3.4

Actual 3.7

Bucket dump spec 1.8 max 2.6

Actual 3?

Swing left or right 3 revolutions from running start 16.4 max 21.7

Actual 11

Propel 20 meters normal speed 21 seconds max speed 13 seconds slow speed 29 seconds

Actual slow 38

Actual normal 20

Actual max 19l

Propel track raised at max speed 3 revolutions from running start spec 14.5 max 19.0

Actual right 21.8

Actual left 20.5 but very shaky and noisy