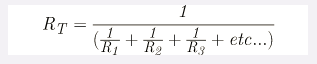

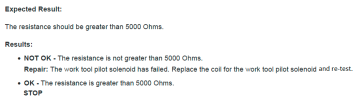

Steps 3 to 5 all state the same thing, they are simply testing a different component (each of the three coils) in each step. The procedure states

"Expected Result:

The resistance should be greater than 5000 Ohms."

You are measuring OL on each of the three steps - or infinite resistance if you will. This measurement is far in excess of the 5000 ohms minimum value from the troubleshooting procedure. Therefore your results in Step 3 to 5 should be considered as

"OK".

The problem is how the text is organized on the page which could be confusing to some people. Until you mentioned it I never took much notice of the detail - all I saw is

"OK - the resistance is greater than 5000 ohms." and literally blanked out the rest of the text because I had all the info I needed.

I have cut & paste the text below to show what it ought to look like in order to be more clearly understood.

View attachment 308118

If the ECM is de-powered it effectively "goes to sleep" (it has no internal battery). This takes a certain amount of time to discharge any capacitors that might be in there. I have no idea what's inside the Interlock ECM TBH, I have never seen the inside of one. Generally you would reckon that 15 minutes should be enough to put any ECM to sleep.

I think what's likely to be happening is that something inside the ECM is either heating up or suffering from vibration, so when you power it from "cold" having disconnected the battery it works fine. However when you change the state of some input into the ECM (such as the armrest switch) whatever is awry inside the ECM goes tilt and fails to work. It may even not be a failing/failed component, it might be nothing more than a soldered joint that has cracked. However it would need the services of a specialist ECM repair shop to test/diagnose/repair.

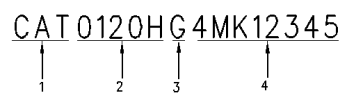

This might interest you. It could be worthwhile giving them a call, but I would suggest that you get a price for a Reman ECM, Part Number 10R8097, before you contact them so that you can compare their repair cost & warranty to that of a replacement ECM