Nige

Senior Member

Sorry, missed that bit. They always seemed to work pretty well whenever I used them.Do you have any thoughts on the temp recorder stickers accuracy?

Sorry, missed that bit. They always seemed to work pretty well whenever I used them.Do you have any thoughts on the temp recorder stickers accuracy?

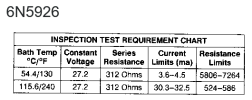

i have no idea. I searched everywhere and could only find that data I posted above. Whether the sender performance between the two mentioned temperatures is linear or something else I'm afraid I have no idea.Based on that what would you expect to be seeing when it reads something in the normal operating range, say 100*c (212*f) at the gauge?

I checked the voltage at the gauge but I missed the bit about the sensor sorry.The sticker will read more accurately on the metal radiator tank than on a rubber hose, the hose is insulating and the surface will be between the coolant temp and the air temp.

Next time, try to determine what voltage the gauges are being supplied with, in older equipment there would sometimes be a voltage stabilizer just for the gauges. I don't know if these gauges do that internally, or if there is still a voltage stabilizer on something like this. I'd check the voltage supplied to the gauges, and then sent to the sensor with the wire disconnected at the sensor, both when you first start, and after a couple hours when they're creeping up.

Well for the sensor test it says 27.2v so I wouldn't think that at a maximum of 27.6 measured you are a million miles away.After warm up at first start, full revs 27.36V

When hot 27.6V (was varying between 27.5-.6)

I was going to run some cleaner/flush through the system before but I thought I had it sorted when I found the earth dramas and the client wanted me to hurry up and get the last few days done on his job so thought I’d test it again and see.i have no idea. I searched everywhere and could only find that data I posted above. Whether the sender performance between the two mentioned temperatures is linear or something else I'm afraid I have no idea.

Just throwing it out there, but have you considered dropping the coolant and running the machine for a while with cooling system cleaner just to see what comes out of the drain plug.? I would say it's worth a shot.

I was typing when you replied. Thanks for the input.Well for the sensor test it says 27.2v so I wouldn't think that at a maximum of 27.6 measured you are a million miles away.

I still vote for getting some cooling system cleaner through the guts of the system and see what colour fluid comes out of the drain.

I wouldn't think so. To get a charge into the batteries of a 24v system you need to generate far more than 24v to force the electrons back in the opposite direction.......e the voltage… it seemed high. Do you think that could be the cause with the gauge reading high?

Yes for charging I thought it was fine but I thought perhaps it might be high for the gauge… thanks for clarifying.I wouldn't think so. To get a charge into the batteires of a 24v system you need to generate far more than 24v to force the electrons back in the opposite direction.......

Usually High system Voltage alarms on electronis machines come on around 30v and VERY HIGH warnings at 32v. I wouldn't think 27.6v is high at all.

What's the ambient temperature range (min/max) in your location.?Also Nige I wanted to pick your brain about transmission oils. The local Cat dealers tell me to only ever run sae30 oil but the book says that for higher temps sae50?

Ah ok that’s what the local Cat guys said too.What's the ambient temperature range (min/max) in your location.?

TBH I used to be a big believer in SAE50 in higher ambient temperatures but not so much now. The downsides of a higher-viscosity oil outweigh the benefitls.

Buy 5 shims by all means + all the other replaceable bits of the converter outlet relief valve, not just the spring.Pulled the outlet relief valve off and apart last night and it has only one spring and no shims. The parts diagrams say it should have an outer and inner spring and lists 5 shims. Nige stated on another tread i was watching that the listed amount of shims is the starting point so I will start from there with new springs.