trkirkendall

Member

Nige, could you possibly get a part number for that spring and the adjustment washers? I can not seem to find it anywhere.

S/N - CAT0257BVSLK03751

S/N - CAT0257BVSLK03751

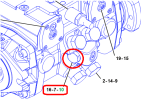

Sorry I got the wrong valve. Assuming that this is the one you are referring to there are no serviceable internal parts. The complete valve #10 is P/N 204-1459. The 3mm thick external shims #7 are available under P/N 204-1456. The O-Ring #16 is P/N 6V-8352.Nige, could you possibly get a part number for that spring and the adjustment washers? I can not seem to find it anywhere.

S/N - CAT0257BVSLK03751