I have a new to me 2003 Cummins N14 STC a non ECM hydroblast pump 475 HP.

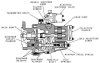

Unit has been sitting a few years, the throttle cable appears to be removed and the linkage on the PT pump has maybe 20 degrees movement. It doesn't feel like it's moving anything just slop.

I have not tried to start the engine the motor turns over using big wrench on alternator bolt freely seems to have good compression.

The tag on PT pump matches engine tag 1921.

So thought of removing the 4 bolts that hold the 301523 part and trying to clean it up and maybe free up the pump levers.

I also checked the shut off solenoid the wire broken off applied 12V Dc with power probe no click so I assume that's gummed jammed up as well.

Wanted to get advice if I should partially tear down the pump and try and free it up before I start taking parts off.

Unit has been sitting a few years, the throttle cable appears to be removed and the linkage on the PT pump has maybe 20 degrees movement. It doesn't feel like it's moving anything just slop.

I have not tried to start the engine the motor turns over using big wrench on alternator bolt freely seems to have good compression.

The tag on PT pump matches engine tag 1921.

So thought of removing the 4 bolts that hold the 301523 part and trying to clean it up and maybe free up the pump levers.

I also checked the shut off solenoid the wire broken off applied 12V Dc with power probe no click so I assume that's gummed jammed up as well.

Wanted to get advice if I should partially tear down the pump and try and free it up before I start taking parts off.