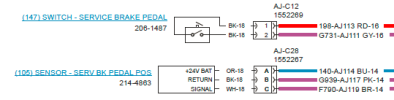

That is the lube feed and little to cause you any bother, the main pressure seemed low as i recall seeing 340 psi recorded, I would have thought the top pressure would have been over 400 + psi (not to tuned in on 6N's) the Brake pressure is always higher than the Transmission as the brakes have to work first, I have had lots of brake issues and often found it to be the priority valve the culprit, by pulling the shafts and looking inwards the amount of lube oil spraying about is crazy, so I never bother with this, even looking through the back plate there always looks to be a massive spray of oil coming from the right F/Drive area, the 2 top coils on the brake valve use PWM to control them, the lower coil/s use 24 volt for the foot brake and park brake.