-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ford 555D hydraulic cylinders

- Thread starter materthegreater

- Start date

materthegreater

Senior Member

Many thanks @Swetz and @NH575E! The kit from CEA was correct, all the seals were perfect match to the originals (minus the deterioration of course!).

I've installed the gland on the rod but have not reinstalled the piston and bolt yet. What torque spec do you guys use, or do you just let the rattle gun go until it won't go any tighter? Red threadlocker on the bolt threads?

I've installed the gland on the rod but have not reinstalled the piston and bolt yet. What torque spec do you guys use, or do you just let the rattle gun go until it won't go any tighter? Red threadlocker on the bolt threads?

NH575E

Senior Member

I use blue loctite and hammer the bolt with a 1" air gun till the compressor cycles back on then let it build and do it again. I have an undersize compressor though. So far I haven't had one come loose.Many thanks @Swetz and @NH575E! The kit from CEA was correct, all the seals were perfect match to the originals (minus the deterioration of course!).

I've installed the gland on the rod but have not reinstalled the piston and bolt yet. What torque spec do you guys use, or do you just let the rattle gun go until it won't go any tighter? Red threadlocker on the bolt threads?

materthegreater

Senior Member

This one had red on the threads when I took it apart, but it also came off with just a 1/2" air impact

rumblecloud

Well-Known Member

This is what mine looked like prior to reassembly:

I had to have mine professionally removed. Admittedly I did not apply heat or really "get after it" as this was my first crack at a cylinder re-seal adventure and I did not want to damage anything. I did do the re-assembly much the same way as @NH575E. Torque specs for these cylinder pistons are unreal and I doubt guys like us (normal, relatively sane), have the necessary equipment to achieve those numbers.

Good luck on yours.

I had to have mine professionally removed. Admittedly I did not apply heat or really "get after it" as this was my first crack at a cylinder re-seal adventure and I did not want to damage anything. I did do the re-assembly much the same way as @NH575E. Torque specs for these cylinder pistons are unreal and I doubt guys like us (normal, relatively sane), have the necessary equipment to achieve those numbers.

Good luck on yours.

NH575E

Senior Member

Those of us with older machines can't really go by what things look like when we take them apart. No telling how many times they have been apart and how many people like me that ignore some specifications and do things our way have been in there.

The question of Loctite type and torque specs comes up from time to time so I went to the E series manual seeking answers.

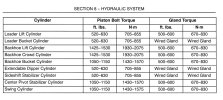

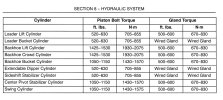

Here are the rod and gland torques listed in the E series New Holland manual.

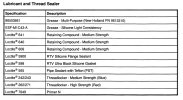

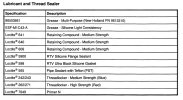

Here is the list of Loctite numbers and types.

My manual calls for the 262/271 High Strength Red for piston bolts and glands. I will continue using 242 Blue on the bolts and anti seize on the glands.

So there you have it. Figure out how or if you want to do it by the book or follow your own path.

The question of Loctite type and torque specs comes up from time to time so I went to the E series manual seeking answers.

Here are the rod and gland torques listed in the E series New Holland manual.

Here is the list of Loctite numbers and types.

My manual calls for the 262/271 High Strength Red for piston bolts and glands. I will continue using 242 Blue on the bolts and anti seize on the glands.

So there you have it. Figure out how or if you want to do it by the book or follow your own path.

Tinkerer

Senior Member

I hope you don't use red loctite on any of the glands.

The are usually a bi to get loose without it. IMHO of course.

The are usually a bi to get loose without it. IMHO of course.

materthegreater

Senior Member

I didn't use heat either.This is what mine looked like prior to reassembly:

View attachment 296989

I had to have mine professionally removed. Admittedly I did not apply heat or really "get after it" as this was my first crack at a cylinder re-seal adventure and I did not want to damage anything. I did do the re-assembly much the same way as @NH575E. Torque specs for these cylinder pistons are unreal and I doubt guys like us (normal, relatively sane), have the necessary equipment to achieve those numbers.

Good luck on yours.

I don't know what New Holland calls for, but this one has a class 10.9 M24-2.00 piston bolt which has a standard torque spec of a little over 800 ft-lbs. Being a D Series it may be a little bit different than the numbers in the chart that NH575E posted.

Swetz

Senior Member

God no! To be honest, as a farm machine, they don't need to be crazy tight. I actually use neversieze on the threads.I hope you don't use red loctite on any of the glands.

Holy Smokes NH. I hadn’t went looking for the torque specs for the crowd cylinder I’m rebuilding now. I thought at the most it was 700-800 lbs. Looks like my battery 3/4 Milwaukee impact is going to have a feast!Those of us with older machines can't really go by what things look like when we take them apart. No telling how many times they have been apart and how many people like me that ignore some specifications and do things our way have been in there.

The question of Loctite type and torque specs comes up from time to time so I went to the E series manual seeking answers.

Here are the rod and gland torques listed in the E series New Holland manual.

View attachment 296995

Here is the list of Loctite numbers and types.

View attachment 296996

My manual calls for the 262/271 High Strength Red for piston bolts and glands. I will continue using 242 Blue on the bolts and anti seize on the glands.

View attachment 296997

So there you have it. Figure out how or if you want to do it by the book or follow your own path.

materthegreater

Senior Member

Well, both the loader bucket cylinder and the steering cylinder are reassembled and seem to be working fine with no leaks so far. Thanks for all the advice!

Swetz

Senior Member

Thanks for the update. I am glad it all worked out!Well, both the loader bucket cylinder and the steering cylinder are reassembled and seem to be working fine with no leaks so far. Thanks for all the advice!