Amjad.kamal

Member

I have a Komatsu PC55-MR3 that I purchased from China and got it shipped here in Calgary, Canada. The machine was dropped at a Komatsu dealership and they filled up the machine with fluids and diesel and performed the following work:

The excavator is now at my place and I am experiencing a major issue with the hydraulics (or at least I think its hydraulics). The engine issues mentioned below are issues but I am not sure if its critical or contributing to the major issue. But I may be wrong. I personally have zero past experience with excavators at all or with hydraulics. However, I've read, re-read and then some more, and continuing to do read the Shop Manual focusing more on all the hydraulic components. So please consider me to be a complete novice.

Hydraulic Issues (Main Issue):

Engine Issues:

What I have checked so far:

Some more History of the Machine:

This is obviously a gray market machine (imported from China). Engine hours and model year cannot be certainly determined. It's a 2019 model allegedly (both the dealer and I highly doubt that's true). Dealer thought maybe anywhere between 2012 to 2015; but it’s just a guess. The seller showed me videos of the machine operational (you decide how much weight you'd want to give that?). The machine was unloaded at local Komatsu dealer in Calgary. I asked them to change the joystick pattern to ISO. If I were to believe that the seller sent a machine that was functional and working; then the hydraulic related issues seems to have started after the dealer changed the pattern. The machine doesn't have a multi-control valve so the dealer must have moved the hydraulic lines and the ppc lines on the control valve. The Machine doesn't have a Control Unit; seems it was pulled out so really can't hook up a computer or anything. The dealer after giving me a big bill basically gave up and asked me to take it work on it myself as my summer project .

.

I am looking for some expert opinions and guidance on what you think may be the issue OR what should be my troubleshooting steps be next. Any help on this would be hugely beneficial for me and much appreciated.

Thanks.

- Filled hydraulic fluid, engine oil & coolant

- Change the hydraulic oil filter, engine oil filter & air filter

- Fixed oil leak from the rear main (broken coupler replaced)

- Changed the joystick pattern from some weird pattern to ISO pattern (saying weird because the service department guy said I've never seen an excavator move like this ever in my life)

The excavator is now at my place and I am experiencing a major issue with the hydraulics (or at least I think its hydraulics). The engine issues mentioned below are issues but I am not sure if its critical or contributing to the major issue. But I may be wrong. I personally have zero past experience with excavators at all or with hydraulics. However, I've read, re-read and then some more, and continuing to do read the Shop Manual focusing more on all the hydraulic components. So please consider me to be a complete novice.

Hydraulic Issues (Main Issue):

- When trying to move the tracks/travel or any of the work equipment (without any load in the bucket) it moves and then suddenly stops (with a small but noticeable jerk; like something tripped). All work equipment and travel stops working (joysticks become unresponsive so does the travel levers). However, the swing and the blade continues to work. Turn the engine off and fire it up again and everything works till it'll happen again under the same circumstances. Few observations below

- If the throttle is set low-medium this happens almost immediately upon trying to move the tracks or lifting the boom.

- Happens almost immediately if boom and arm are operated at the same time at low-medium throttle.

- At full throttle, I am able to move the equipment very gradually and slow. If pushed too much or too quickly it would result in the same issue described above.

- Even at full throttle the engine seems to bog down a little when putting the load before the hydraulics function for the work equipment trips. However, I have noticed the hydraulics tripping even without noticeable bogging down of the engine.

Engine Issues:

- The engine (Yanmar 4D88E-5XA) seems to be misfiring at full throttle

- Engine produces excessive white smoke at the start and for about 15-20 mins till it fully warms up (smoke significantly reduces but still present)

- Engine Oil excessively black despite being recently changed (2 months ago and hardly any run time)

What I have checked so far:

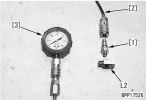

- Checked Unload Pump Pressure: Within specs of standard value ~500psi

- Checked the relieve pressure of the boom, arm, bucket & Travel

- Boom, arm & bucket relief are ~900 psi higher the standard value as per the workshop manual (4700psi vs 3845 psi)

- Travel relief pressure ~590 psi lower than standard value (3250psi vs 3845)

- Checked Swing & Blade relief pressure

- Swing relief pressure is about 250 psi higher (3100 psi vs. 2845psi)

- Blade relief pressure is ~3200psi right around where it should be (3200psi vs. 3133 psi)

- Checked the Hydraulic Oil filter for any metal shavings or glitter - none whatsoever

Some more History of the Machine:

This is obviously a gray market machine (imported from China). Engine hours and model year cannot be certainly determined. It's a 2019 model allegedly (both the dealer and I highly doubt that's true). Dealer thought maybe anywhere between 2012 to 2015; but it’s just a guess. The seller showed me videos of the machine operational (you decide how much weight you'd want to give that?). The machine was unloaded at local Komatsu dealer in Calgary. I asked them to change the joystick pattern to ISO. If I were to believe that the seller sent a machine that was functional and working; then the hydraulic related issues seems to have started after the dealer changed the pattern. The machine doesn't have a multi-control valve so the dealer must have moved the hydraulic lines and the ppc lines on the control valve. The Machine doesn't have a Control Unit; seems it was pulled out so really can't hook up a computer or anything. The dealer after giving me a big bill basically gave up and asked me to take it work on it myself as my summer project

I am looking for some expert opinions and guidance on what you think may be the issue OR what should be my troubleshooting steps be next. Any help on this would be hugely beneficial for me and much appreciated.

Thanks.

Last edited: