Yeah Bob, your machine looks awesome. I got it for putting up timber frame buildings on my property, I can certainly tolerate it being a little rough for a while. What I hear is the thing sat for about 15 years-ish prior to my acquiring it. It must have had a mostly full hydraulic tank, cause the inside is shiny metal below a certain point.

Doesn't this strainer just keep you from pouring trash into the tank, when filling with oil? If so, if you can manage to fill it with clean oil, I don't know that I would lose sleep over the strainer being gone.

My understanding is that this separates the suction side of the tank from the fill/return side? The manual says:

A double element filter is provided in the bottom of the hydraulic tank to filter all oil as it returns to the tank.

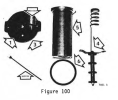

From the parts diagram and picture below (correct me if I'm wrong) but it looks like the oil is returned to the top of the tank, where it is sucked down through that screen which, I'm guessing, slows the flow around the magnets and provides an additional layer of filtering?

I can't tell if it was lost recently or ran for a while without it, the spider is there. Given some of the rust flakes and dirt I found in the top of the tank, I'm thinking I better be more cautious, as I don't want to have to rebuild the pump if I can avoid it for a while.

Here's my short list:

- DONE - Remount/Inner Tube right rear tire.

- DONE - Clean out all the crud and power wash the slime

- Repair broken cover stud on hydraulic tank

- Clean hydraulic tank and install new filters/screen

- Replace broken shift cable

- Unstick/Swap fast lift cable for testing

- Reattach hydraulic pump drive shaft (we detached it so the pump wouldn't run dry)

- Reattach lower boom cylinder end to boom (I think one of the owners was about to reseal it then stopped or injured himself or something)

Thanks for your help / advice guys. It's nice to know there are others out there with these things.